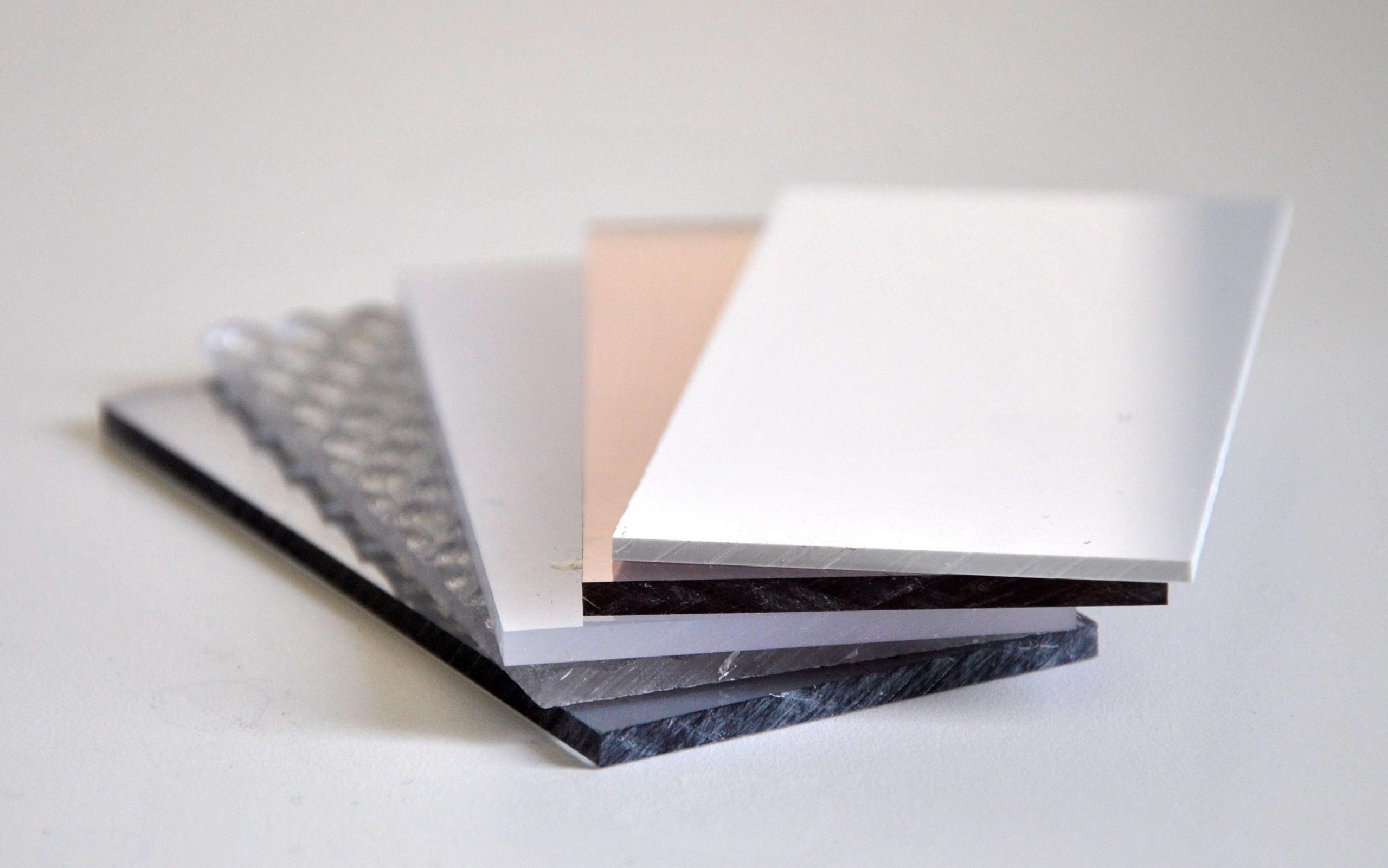

PLASTIC MATERIALS

THE ADVANTAGES OF PLASTIC MATERIALS

The main properties of plastic materials:

- Lightweight

- Good sliding properties

- High mechanical resistance

- Resistance to deterioration and abrasion

- Resistance to high or low temperature

- Resistance to corrosion

- Chemical resistance

- Absorption of vibration and noise

- Compatibility with foodstuffs FDA ;(1935/2004/CE, 2002/72/CE)

The range is wide and the properties vary according to the level of technicality. Plastics have many advantages over ferrous and non-ferrous metals.

Technical DATA SHEETS

STANDARDS <80°C

PEHD 300 – Polyethylene

PE 500 , PE-HMW– High molecular weight polyethylene

PE-UHMW – Ultra high molecular weight polyethylene (TIVAR®, BOROTRON®)

TECHNICAL 80 à 160°C

PA , Nylon – Polyamide (ERTALON®, NYLATRON®)

POM C , POM H – Polyacetal (DELRIN®, ERTACETAL®, ACETRON®)

PET-P – Polyethylene therphtalate (ERTALYTE®)

PC 1000 – Mechanical polycarbonate (MAKROLON®, LEXAN®)

ADVANCED 160 à 220°C

PEEK – Polyetherethercetone (KETRON®)

PPS–Polyphenylene sulfide (TECHTRON®)

PVDF –Polyvinylidene fluoride (SYMALIT®)

PPSU – Polyphenylsulfone (SULTRON®)

PTFE – Polytetrafluoroethylene(FLUOROSINT®)

EXTREME TECHNICAL >220°C

PAI – Polyamide-imide (DURATRON®)

PI – Polyimide (MELDIN®, VESPEL®)

PBI – Polyenzimidazole (TORLON®, DURATRON®)

Thermoplastics for boiler making

PVC – PVC Transparent – Polyvinyl chloride

PEHD 300 – Polyethylene

PP – Polypropylene

PMMA acrylic – Polymethylene methacrylate (PLEXIGLAS®, ALTUGLAS®)

PC – Optical polycarbonate (MAKROLON®, LEXAN®)

PETG – Polyethylene terephthalate (VIVAK®, AXPET®)

recycled thermoplastic

On demand

CHOOSE THE RIGHT PLASTIC

We offer a wide range of plastic materials imported directly from our manufacturers.

The available formats are :

- Plate

- Tube

- Rod / Round Bar

Steps to choose the right material

1- Determine the function of the part

- Support and wear application or structural application (static or dynamic)

2- Consider the thermal requirements of your application

- Under normal and extreme operating conditions

3- Consider chemical exposure

- During use and cleaning

4-Consider the aesthetics of the part

- Part appearance

5-Select the right size to produce the part

- Plate, Round Bar or Tube.

- Size and thickness.

6- Make sure you get the right material

- Ask for the material certificate of conformity at the time of the order. Our team will assist you in this process.

A CUSTOM-MADE SERVICE

Cutting and planing

- Plate/Sheet

Up to a thickness of 120mm

- Bar and tube

Up to a dimeter of 400mm

We deliver the cut materials to your dimensions whatever the format.

Rectifying

- Bar diameter 3 to 80mm

- Accuracy to the 100th of a mm

- Surface finish

Our factory in Thyez, specialized in the grinding of plastic and composite bars, is located in Haute-Savoie (74), in the heart of the Arve valley. (capital of turning in France.)

OUR BUSINESS COMMITMENT

- You find a quality in hospitality and advice.

- You benefit from attractive pricing conditions. We work directly with manufacturers.

- You get a quote within 2 hours.

- You rely on a large stock of materials. We receive 5 tons of goods per day.

- You are delivered in 48 hours. We make more than 100 deliveries daily throughout France.