COMPOSITE MATERIALS

THE ADVANTAGES OF COMPOSITE MATERIALS

Composite material has many advantages

- Lightweight, with a density between 1.35 and 2.35.

- Fire resistance, svt standards: UL94 / EN45545

- Chemical resistance

- Rot-proof

- Dielectric insulation, up to 20Kv/mm

- Good mechanical support, with a modulus of elasticity up to 24Gpa

- Heat resistance, up to 1000°C (and for some 100% non-combustibility).

- Low thermal conductivity

Composition of the composite material

The composite material is made of at least two distinct components. A fiberglass reinforcement structure and a resin matrix (binder).

- The properties of the material become superior to those of each component.

- It has intrinsic physical, dielectric, mechanical and chemical characteristics.

TECHNICAL DATASHEETS

Phenolic laminates 120°C

BAKELISE PAPER – Cellulose paper base and phenolic resin

BAKELISE TOILE – Cotton base and phenolic resin

BAKELISE WOOD – Wood base and phenolic resin

Glass Laminates – Polyester / Epoxy / Silicone / Melamine 130 à 300°C

GLASS MAT – Polyester resin

GLASS MAT – Epoxy resin

GLASS FABRIC – Epoxy resin

GLASS FABRIC – Conductive

GLASS FABRIC – Silicone resin

GLASS FABRIC – Melamine resin

GLASS ROVING – High Temperature Resin

Mica Laminates Silicone Resin 500à 700°C

MICA MUSCOVITE – Silicone resin

MICA PHLOGOPITE – Silicone resin

Refractory cements 500 à 700°C

CIMENT 700 – Cement and inorganic fiber base

Silicates 500 à 1000°C

MONALITE M1/M1A

D1000

A WINNING ALTERNATIVE

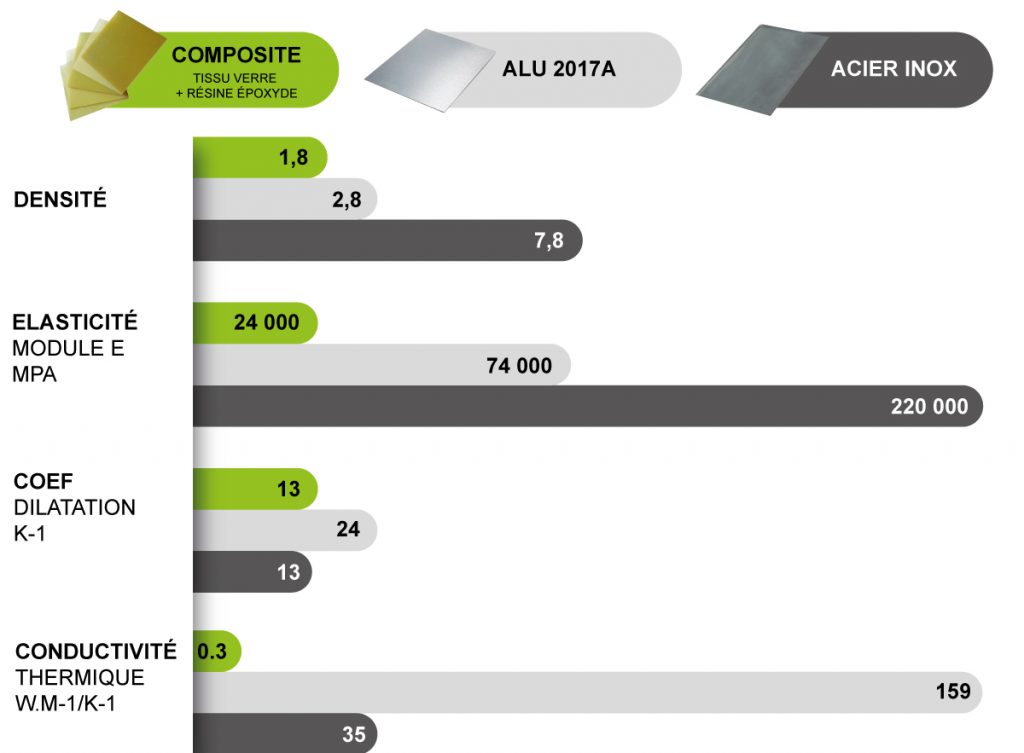

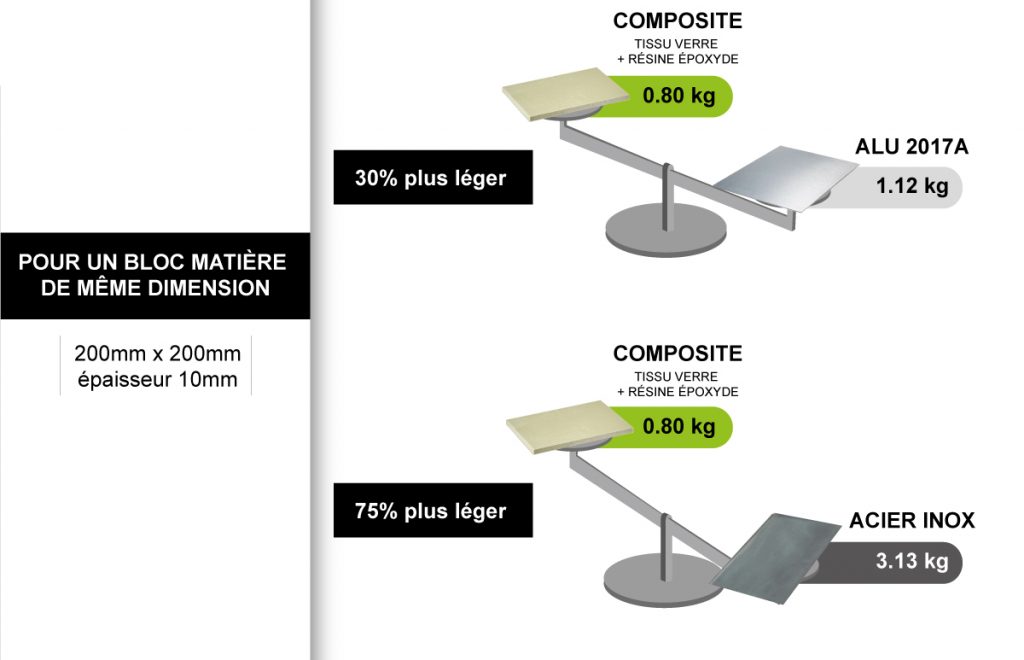

The composite material is becoming a real alternative to other materials such as ALU 2017A or stainless steel.

In comparison with the other two, here are the main performances:

A CUSTOMIZED SERVICE

Cutting and planing

- Plate/Sheet

Up to a thickness of 120mm

- Bar and cylinder

Up to 600mm diameter

We deliver the materials cut to your dimensions whatever the format.

Grinding

- Bar diameter 3 to 80mm

- Precision at 100 mm

- Surface condition

Our factory in Thyez, specialized in the grinding of plastic and composite bars, is located in Haute-Savoie (74), in the heart of the Arve valley (capital of turning in France.)

YOU HAVE A PROJECT?

ICM Industrie supports you in the choice of materials, design, qualification and manufacture of prototypes, medium and large series.